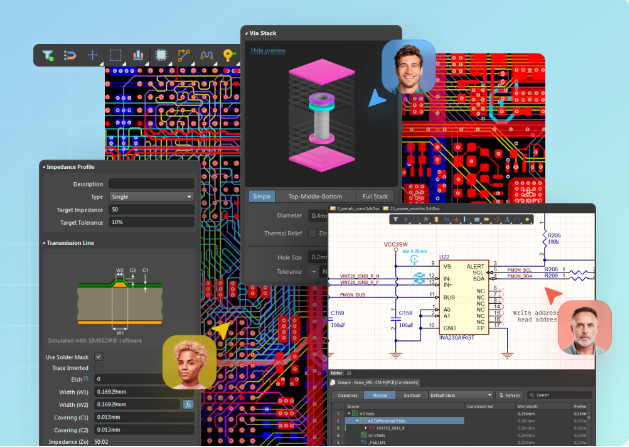

Altium is one of the best-known vendors in electronic design automation (EDA) focused on PCB design and electronics product development. Its flagship desktop product, Altium Designer, together with cloud services such as Altium 365 and collaboration/enterprise offerings, positions the company as a one-stop environment for schematic capture, PCB layout, simulation, mechanical co-design, data management and manufacturing output. Below I’ll explain the platform, key technical details, how teams typically use it, and concrete use-case examples.

Altium Designer is a unified electronic design environment that brings schematic capture, PCB layout (2D & Native 3D), rules/constrains, simulation, BOM management and output job generation into a single application. Altium’s cloud platform, Altium 365, connects designers, supply-chain and manufacturing stakeholders for collaboration, traceability and cloud workspaces. Together they target everything from single-engineer prototypes to multi-discipline teams and enterprise workflows.

Altium combines decades of PCB/EDA experience into a polished, highly integrated toolset targeted at modern hardware teams. Its combination of desktop power (Altium Designer), scripting/SDK extensibility, and cloud-native collaboration (Altium 365) makes it a strong choice for teams aiming to reduce iteration cycles, enforce manufacturability and scale hardware development.

Core capabilities (technical summary)

Unified design environment

- Single data model across schematics, PCB and 3D mechanical (Native 3D) so edits maintain design intent across editors. This reduces translation friction between schematic changes and the board layout.

Schematic capture & multi-sheet projects

- Hierarchical multi-sheet schematics, net-connectivity, annotated part links and variant configuration support.

PCB layout and advanced board capabilities

- 2D layout with full high-speed/HDI rule support, plus Native 3D view to verify mechanical clearances and export MCAD models. Rigid-flex board design features are supported for combined rigid and flex layers.

Design rules and constraint management

- Constraint-driven flows (clearance, impedance, routing, manufacturing constraints) and a Constraint/Rule Manager to formalize manufacturability and signal integrity rules.

Simulation and verification

- Integrated mixed-signal simulation for circuit checking, plus DRC/DFM checks and output preview to catch issues before fabrication.

Manufacturing output & formats

- Generates the usual manufacturing deliverables: Gerber (including modern Gerber X2/X3), ODB++, IPC-2581, NC Drill, pick-and-place, BOMs and assembly data. Support for intelligent outputs (IPC-2581/ODB++) enables better CAM/DFM handover.

Scripting & automation / SDK

- Automation via the built-in scripting system (default language: DelphiScript). Altium also supports running legacy VBScript and JScript, and provides an SDK / Extension API (with example units for Delphi, C# and C++) so teams can build extensions, automated exporters, batch tools and custom integrations. Altium 365 also exposes REST and Python APIs for cloud interactions and automation.

Platform / collaboration

- Altium 365: secure cloud workspace for sharing projects, component libraries, supply-chain data and collaborative review across teams. It also enables cloud-based review, versioning and links between requirements and design objects.

Supported platforms & system requirements

- Altium Designer is formally supported on 64-bit Windows (Windows 11/10 recommended). Typical minimums listed include an Intel Core i5 (or equivalent), ~4 GB RAM (real designs require much more), a DirectX-capable GPU and disk space for install and user files — production use strongly benefits from higher CPU/RAM/SSD. Running native on macOS requires virtualization/Windows.

Technical details engineers care about

- File outputs: Gerber X2/X3, standard Gerber, ODB++, IPC-2581 (intelligent single-package exchange), NC drill, pick-and-place, BOM (CSV/Excel) and a rich Output Jobs system to customize delivery per vendor. These are essential for CAM and contract manufacturer handoff.

- 3D & MCAD integration: Native 3D view plus MCAD exchange (STEP/IGES) for mechanical verification and enclosure fit.

- High-speed & signal integrity: Constraint management for impedance control, controlled routing and integration with SI analysis flows.

- Rigid-Flex: explicit layer stack and bend region support, with cross-editor visualization to check bend areas, stiffeners and material definitions.

- Automation & extensions: scripting (DelphiScript), SDK for compiled extensions in C#/C++, and cloud APIs (REST/Python) to integrate with PLM, issue trackers or custom build/DFM pipelines.

Typical real-world use cases (with examples)

- Consumer electronics prototype → production ramp (startups, hardware teams)

- Flow: schematic → layout → 3D verification → DFM output → CAM (Gerber/IPC-2581) → fabrication.

- Why Altium: single environment shortens iterations; built-in BOM & supplier links speed procurement; Output Jobs create turnkey manufacturer packages.

- High-speed / RF product (networking, comms)

- Altium’s rules/constraint engine and stackup configuration help enforce impedance and length matching. Pair with SI tools or simulation to validate critical nets before boards are sent to fab.

- Rigid-flex for wearables & medical devices

- Devices needing folded/flexible sections use Altium’s rigid-flex layer definitions and bend region analysis to ensure manufacturability and lifespan.

- Multi-discipline teams (mechanical + electrical) — industrial & automotive

- Native 3D plus STEP export and Altium 365 collaboration keeps MCAD/ECAD aligned, preventing enclosure clashes and saving rework.

- Enterprise teams needing component governance & traceability

- Altium 365 and on-prem Enterprise Server (formerly Concord/Concord Pro lineage) provide controlled component libraries, revisioning, and cross-team access controls, useful in regulated industries like aerospace or medical.

Unified Electronics Development for Modern Engineers | Altium