Cellares, a South San Francisco–based pharmaceutical firm on a mission to accelerate access to critically important therapies. Utilizing a network of smart factories and a vertically integrated business model, the company offers a radical reimagining of how cell therapies can be made, from development to manufacturing to regulatory support. And—just as significant—it presents an easier path to scalability.

Key Innovations

- Network of Smart Factories:

- Decentralized Manufacturing: By leveraging advanced automation and digital infrastructure, Cellares’ smart factories are designed to produce cell therapies at scale, closer to patients, and with enhanced precision.

- Flexibility: These facilities can handle a variety of therapy types, from CAR-T therapies to stem cells and other emerging modalities.

- Vertically Integrated Business Model:

- Development to Delivery: By controlling every stage—from development to production to regulatory support—Cellares offers a seamless and efficient pathway for its partners.

- Reduced Complexity: This integration minimizes handoffs, reduces delays, and optimizes cost structures.

- Scalability Simplified:

- Traditional cell therapy manufacturing processes struggle with scalability due to their manual, labor-intensive nature. Cellares’ technologies, such as automation and advanced bioprocessing systems, enable rapid and cost-effective scaling.

- Advanced Automation:

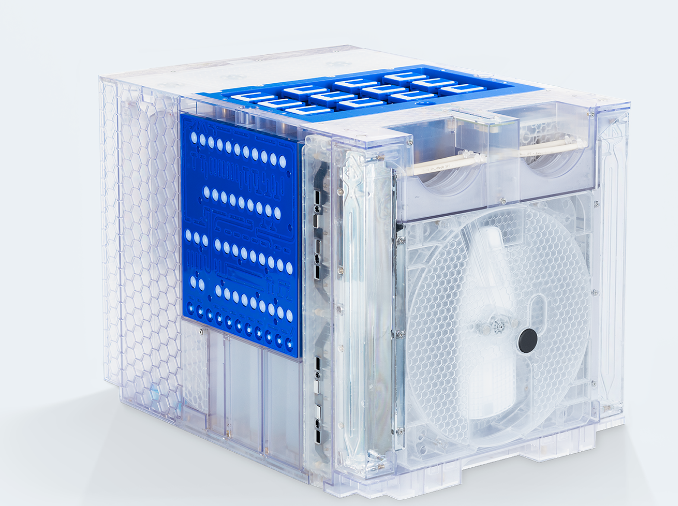

- Proprietary technologies automate traditionally manual processes, increasing reproducibility and reducing human error.

- This ensures consistent quality across batches and compliance with stringent regulatory standards.

- Regulatory Support:

- By integrating regulatory expertise into their offerings, Cellares helps accelerate time-to-market for therapies while ensuring compliance across multiple jurisdictions.

Advantages of Cellares’ Approach

- Cost Reduction:

Streamlined operations and automation lead to significant cost savings, making therapies more accessible. - Faster Market Entry:

Integrated services and smart manufacturing speed up the time needed to bring therapies from development to patients. - Higher Accessibility:

Distributed smart factories make it feasible to localize production, reducing logistical complexities and improving access globally. - Consistent Quality:

Automated systems reduce variability and improve the reproducibility of therapies, which is critical for patient safety and regulatory compliance.

Cellares – The First Integrated Development and Manufacturing Organization (IDMO)