Kapton tape supercapacitors built using Laser-Induced Graphene represent one of the most accessible and scalable approaches to flexible energy storage. By directly converting inexpensive polyimide into conductive, porous graphene foam, researchers can create high-performance supercapacitors suitable for wearables, IoT devices, robotics, and smart textiles.

LIG-based supercapacitors combine simplicity, low cost, flexibility, and high power density, positioning them as a cornerstone for the next generation of flexible and printable electronics.

A Kapton Tape Supercapacitor is a tiny energy-storage device made using Kapton tape, a special heat-resistant plastic film. Kapton is normally used for insulation in electronics, spacecraft, and flexible circuits. But researchers discovered that it can also be used to make flexible, lightweight supercapacitors.

What is a Supercapacitor?

A supercapacitor is like a battery that charges very fast and can release energy quickly.

It doesn’t store as much energy as a battery, but it can last for thousands of charge cycles and is excellent for quick bursts of power.

Why Kapton Tape?

Kapton has unique properties:

- It can handle extreme heat and cold.

- It is flexible.

- It has a smooth and stable surface.

- It can be easily modified to become electrically conductive when treated or laser-engraved.

When Kapton tape is burned or engraved with a laser, its surface turns into porous carbon, which is perfect for storing electrical charge. This carbon layer becomes the active material of the supercapacitor.

How It Works

- A laser engraves a pattern on Kapton tape.

- The engraved area becomes graphene-like porous carbon.

- This carbon acts as the electrode of the supercapacitor.

- Two such electrodes are placed together with a gel electrolyte.

- The result is a thin, flexible supercapacitor.

Where It Can Be Used

Kapton tape supercapacitors are useful in:

- Wearable electronics

- Flexible sensors

- Mini robots

- Medical patches

- IoT (Internet-of-Things) devices

- Any device that needs light, fast-charging power

Why It’s Exciting

This technology is cheap, simple, and can be made at home with the right tools (like a laser engraver). It opens the door to ultra-thin, bendable power sources that can be placed almost anywhere.

1. Introduction

Supercapacitors (electrochemical capacitors) are energy storage devices characterized by:

- High power density

- Ultra-fast charge/discharge capability

- Long cycle lifespan

- Low internal resistance

Traditional supercapacitor electrodes require complex materials engineering, but Laser-Induced Graphene (LIG) has emerged as a breakthrough technique that allows researchers and engineers to directly write porous graphene onto inexpensive substrates like Kapton tape (polyimide).

This process transforms a low-cost, flexible polymer into a graphene foam electrode suitable for high-performance supercapacitors, flexible electronics, IoT hardware, biosensors, and wearable systems.

Kapton-based LIG supercapacitors are particularly attractive for low-cost, printable, flexible, solid-state power storage.

2. What Is Kapton (Polyimide)?

Kapton is a polyimide film known for:

- Excellent thermal stability

- Chemical resistance

- Mechanical strength

- Extreme flexibility

- High dielectric strength

Chemically, it contains aromatic rings with carbon, nitrogen, oxygen, providing a carbon-rich structure ideal for laser carbonization.

Kapton tape is widely used as:

- Electrical insulation tape

- Laboratory high-temperature tape

- 3D-printer bed tape

- Dielectric substrate in electronics

These qualities make it a perfect precursor for creating graphene-based electrodes using LIG.

3. Laser-Induced Graphene (LIG): Fundamental Process

LIG was developed by Rice University and is one of the most accessible ways to fabricate graphene.

3.1 How LIG Works

A CO₂ IR laser (~10.6 µm wavelength) is rastered across a polyimide surface.

The laser energy:

- Breaks chemical bonds

- Causes rapid photothermal decomposition

- Reforms carbon atoms into turbostratic, porous graphene foam

This foam consists of:

- Multilayer graphene

- Defect-rich graphene

- 3D porous conductive networks

- High-surface-area carbon microstructures

The transformation is localized and instantaneous — creating conductive patterns directly from the polymer.

3.2 Why Graphene Foam Is Ideal for Supercapacitors

Graphene foam provides:

- Very high electrochemical surface area

- Excellent electron mobility

- High porosity for ion transport

- Mechanical flexibility

4. Converting Kapton into Graphene Foam

4.1 Laser Parameters

Typical values:

- Laser power: 2–12 W (CO₂ laser)

- Focus height: Defocused for thicker foam

- Scan speed: 5–50 mm/s

- PPI/DPI: 300–1200

Higher power/time creates deeper, more porous graphene.

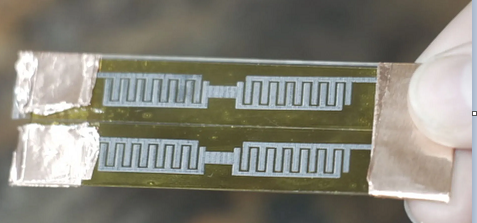

4.2 Electrode Design

Patterns can be written into:

- Interdigitated electrodes

- Square pads

- Multi-layer stacks

- Microsupercapacitors

Laser passes define both electrodes in a single step.

4.3 Foam Structure

The resulting graphene:

- Is ~50–200 microns thick

- Has 3D porosity

- Includes microchannels and nano-flakes

- Shows resistivity in the range of 10–30 Ω/sq

5. Building the Kapton Tape Supercapacitor

5.1 Basic Structure

A solid-state LIG supercapacitor typically uses:

Top Electrode: LIG on Kapton

Bottom Electrode: LIG on Kapton

Electrolyte:

- PVA/H₃PO₄ gel

- KOH/PVA gel

- LiCl/PVA gel

- Ionic liquids

- Hydrogel electrolytes

Separator:

- Paper

- Gel layer

- Polymer film

Flexible, bendable, and printable.

5.2 Fabrication Steps

- Clean Kapton tape

- Laser-scribe graphene pattern

- Apply gel electrolyte

- Laminate two electrodes face-to-face

- Cure electrolyte

- Test with CV, GCD, EIS

Entire process can be done on a desktop laser cutter.

6. Performance Characteristics

Kapton-LIG supercapacitors typically exhibit:

Electrochemical properties

- Capacitance: 10–20 mF/cm² (single layer)

- Energy density: 1–8 mWh/cm³

- Power density: 10–500 W/cm³

- Cycle life: 10,000 to 100,000 cycles

Mechanical properties

- Stable under bending

- Maintains performance under repeated flexing

- Can be cut, rolled, or folded

Electrical properties

- High electrical conductivity

- Low resistance paths for rapid discharge

These characteristics enable practical, miniature, and flexible power sources.

7. Advantages of Kapton-Based LIG Supercapacitors

- Low cost – Materials cost is under $1

- Scalable – Can be mass-produced or desktop-manufactured

- Flexible & Wearable – Ideal for smart clothing and rollable devices

- No toxic chemicals – Polymer base + safe gel electrolytes

- No cleanroom required – Can be built in a standard lab

- High surface area graphene – Much better than traditional carbon electrodes

- Customizable – Patterns can be written digitally in minutes

8. Application Use Cases (Comprehensive List)

A. Wearables & Smart Textiles

- Health monitoring patches

- Smart clothing

- Flexible biometric sensors

- Motion-detection garments

- Energy harvesting + storage systems

B. IoT Devices

- Tiny sensor nodes

- Environmental monitors

- Wireless micro-sensors

- Low-power embedded circuits

- Smart home micro-power units

C. Robotics / Drones

- Lightweight power buffers

- Flexible sensor skin power supply

- Micro-actuator power support

- Onboard power conditioning

D. Biomedical Devices

- Skin patches

- Drug delivery systems

- Epidermal electronics

- Prosthetic sensor modules

- Temporary medical implants (short-duration)

E. Consumer Electronics

- Rollable displays

- Flexible keyboards

- E-paper readers

- Touch panels

- NFC modules

F. Energy Harvesting Systems

Paired with:

- Triboelectric nanogenerators

- Piezoelectric harvesters

- Thermoelectric harvesters

- Solar thin films

Supercapacitors store the harvested energy.

G. Microelectronics & Chip-Level Applications

- On-chip power delivery

- Microsupercapacitors

- Memory backup

- Voltage smoothing

- Power conditioning

H. Education & Research

- Graphene fabrication teaching

- DIY electronics

- University labs

- Maker projects

- Rapid prototyping

I. Industrial and Military

- Rugged flexible power sources

- Harsh environment electronics

- Sensor networks

- Miniature power buffers

- Tactical smart fabrics

J. Emerging Areas

- Smart packaging with electronics

- Digital tattoos

- Human-machine interface patches

- Low-power AI edge modules

9. Challenges and Limitations

- Electrolyte drying reduces lifespan

- Energy density lower than Li-ion batteries

- Moisture sensitivity in some electrolytes

- Laser tuning required for optimal graphene

- Not suitable for high-energy applications

Ongoing research focuses on improving ionic conductivity, encapsulation, and foam morphology.

10. Future Directions

Hybrid Materials

- Metal oxide-coated LIG

- LIG + MXene

- LIG + conductive polymers (PEDOT:PSS)

3D Printing + LIG

Additive manufacturing of fully flexible power circuits.

Ultra-thin LIG microsupercapacitors

For implantable devices or chip-level integration.

Mass manufacturing

Roll-to-roll laser systems could produce kilometers of LIG electrodes.