An MIT-led group of researchers has claimed to have determined a way to make large sheets of molybdenum telluride.

Sheets of graphene and other materials that are virtually two-dimensional hold great promise for electronic, optical, and other high-tech applications but the biggest limitation in unleashing this potential has been figuring out how to make these materials in the form of anything larger than tiny flakes.

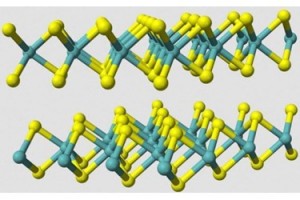

Now researchers at MIT and elsewhere may have found a way to do so. The group has determined a way to make large sheets of one such material, called molybdenum telluride, or MoTe2. The team says their method is also likely to work for many similar 2-D materials, and could make widespread applications feasible.

This material has a similar bandgap to silicon, a characteristic needed in order to make transistors and solar cells and in single-layer form it has a direct bandgap which allows better light emission. It also has strong absorption for solar radiation which is key to making practical solar cells.

This makes Molybdenum telluride (MoTe2) key to making solar cells and transistors and it also lends itself to applications in spintronics. MoTe2 can exist in two different forms; one is metallic, meaning it conducts electricity well, and the other is a natural semiconductor, lending itself to applications in electronics. Controlling how the material is made, allows the researchers to create whichever form is needed for a particular use.

The method of creating these large sheets is based on chemical vapor deposition (CVD), and this makes it possible to create sheets of any thickness, and of a size limited only by the dimensions of the CVD chamber used for deposition. One challenge the team had to overcome was that the atoms of molybdenum telluride are weakly bound to each other, so the tendency of the two precursor materials to form molybdenum telluride is low. The researchers were able to overcome this by using several stages of deposition, beginning with a layer of pure molybdenum. This method makes it easy, because you only need to control one material. This step is followed by oxidation of that layer in which this material is then removed and powdered tellurium is added and vaporized in a carrier gas of hydrogen and argon, at a temperature of 700°C. The use of hydrogen in the process is crucial to producing a uniform MoTe2 film. This process can grow sheets that have a very large area, are very homogeneous, and have high quality.

The team now aims to explore adapting this process to create large sheets of other promising thin materials. They will examine whether versions of the process can work with other compounds.

Physicist Ado Jorio of the Federal University of Minas Gerais, Brazil, who was not involved in this work, says, “What is most impressive is that this group has been able to consecutively develop new formulae to produce almost any low-dimensional material they want, always scalable with the highest quality worldwide.

Vincent Meunier, a physicist at Rensselaer Polytechnic Institute who was also not associated in this research, adds, “One of the many advantages of the proposed approach stems from its simplicity.’’

The consequences of this development are likely to be numerous, as it provides a versatile and scalable technique to develop macroscopic amounts of atomically thin films, thereby surmounting major roadblocks faced by layered-materials based research so far.

For more information please visit: www.news.mit.edu