Wood is made of two basic ingredients: cellulose, which are tiny fibres, and lignin, which bonds those fibres together to give it strength.

Tear a paper towel in half and look closely along the edge. You will see the little cellulose fibres sticking up. Lignin is a glue-like material that bonds the fibres together, a little like the plastic resin in fibreglass or carbon fibre. The lignin also contains molecules called chromophores, which give the wood its brown colour and prevent light from passing through.

Early attempts to make transparent wood involved removing the lignin, but this involved hazardous chemicals, high temperatures and a lot of time, making the product expensive and somewhat brittle. The new technique is so cheap and easy it could literally be done in a backyard.

UMD researchers have created a clear alternative to building materials that insulate poorly or keep interiors dark: transparent wood.

Researchers in the university’s Energy Research Center have developed this material, which allows sunshine to pass through, like frosted glass, but can’t be smashed and is more energy-efficient than typical glass windows.

A team of researchers led by Associate Professor Liangbing Hu describe their work developing translucent wood in a paper in the journal Advanced Materials, and recently launched a startup called Inventwood LLC. The team also published a paper on advanced energy materials describing how transparent wood can be an energy-efficient building resource.

The process starts with immersing a 4cm square of wood in a cocktail of chemicals that removes the lignin, the substance that gives wood its brown color, and then infusing the newly translucent block with epoxy to harden it.

Clear Cuts

Wood doesn’t conduct heat as easily as glass, so instead of heat escaping through a window in the winter and seeping in during the summer, it is trapped inside and blocked outside, keeping the indoor temperature more consistent. Even the grain of the wood is useful.

“You have these very special channels that can guide visible sunlight into the house, independent of where the sun is,” says Tian Li Ph.D. ’15 (above, left), a postdoctoral associate and lead author of the study.

The researchers say the primary challenge now is to develop techniques that allow for them to create larger pieces.

“Right now the scale is a problem, because for any real application you would need at least palm-sized or bigger,” says Amy Gong (above, right), another postdoctoral associate. “We’re limited to the container’s shape.”

The team is also working to decrease the haziness of the wood, hoping to reach the clarity offered by glass windows. Users can easily see objects on the other side of the product only when they are close.

Despite the current limitations, the technology is immensely promising, researchers say.

“Transparent wood can generate tremendous energy savings in daytime lighting and air-conditioning,” Li says.

Starting with planks of wood a metre long and one millimetre thick, the scientists simply brushed on a solution of hydrogen peroxide using an ordinary paint brush. When left in the sun, or under a UV lamp for an hour or so, the peroxide bleached out the brown chromophores but left the lignin intact, so the wood turned white.

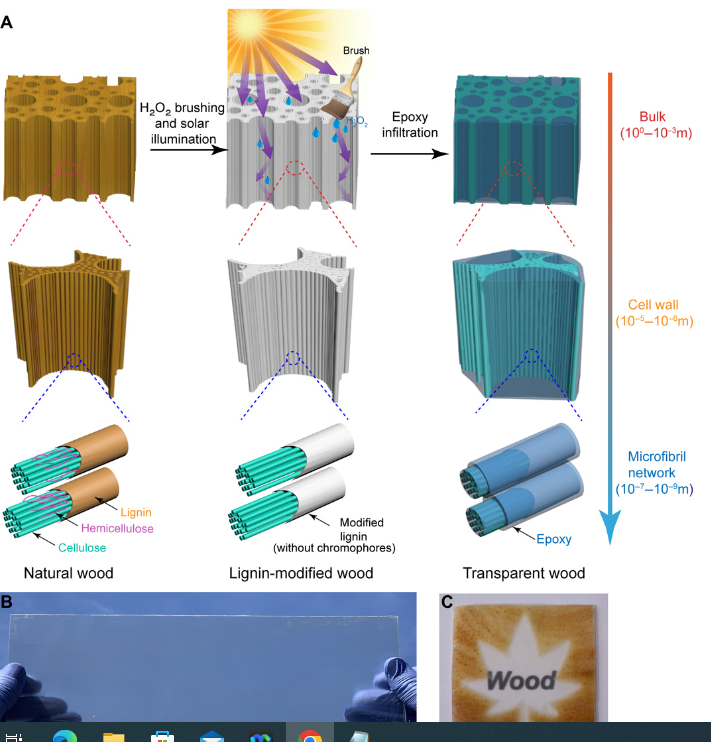

a technique for rapidly fabricating transparent wood that involves chemical brushing, rather than immersion, combined with solar illumination to remove the lignin chromophore. Figure shows the fabrication process of the transparent wood via a two-step approach. First, we modify the lignin structure by brushing H2O2 across the wood surface, followed by ultraviolet (UV) light illumination that can be conducted using natural sunlight to remove the light-absorbing chromophores of lignin. Refractive index matching epoxy can then be easily infiltrated into the microporous wood structure to prepare the transparent wood, which features a dense microstructure and low light scattering.

The hierarchically porous structure of natural wood promotes fast H2O2 solution infiltration/diffusion and UV light trapping to efficiently remove the light-absorbing chromophore of lignin, significantly reducing its light absorption (<4%). Compared to lignin-removed wood (0.4 MPa), the lignin-modified wood also shows a substantially higher tensile strength (20.6 MPa) due to the presence of the modified lignin binding with the well-oriented cellulose fibrils, which provides a strong and robust scaffold for polymer infiltration. Note that transparent wood can be made from both transversely and longitudinally cut natural wood, respectively (Fig. 1, B and C). The resulting transparent wood exhibits a high transmittance (up to ~90%), excellent tensile strength (> 46 MP), and favorable light guiding effect. In addition, the transparent wood can be easily patterned using this chemical brushing combined with UV light illumination method. Compared with traditional solution-based immersion processes, our method requires fewer chemicals and energy consumptions, thus greatly reducing the preparation cost and liquid waste. This environmentally friendly, scalable, patternable, and low-cost transparent wood with favorable optical and mechanical properties holds great potential in energy-efficient building applications and light management devices.

https://www.usda.gov/media/blog/2020/10/01/transparent-wood-could-be-window-future