3D Bioprint Service

Three-dimensional (3D) bioprint, otherwise termed additive manufacturing, is driving major innovations in many fields, including manufacturing, engineering, art, education and medicine. Although a newly established technology, 3D bioprint has been developed at a rapid growth during the last decade. This approach helps to achieve increasingly cell-based therapies by working with diverse materials, like plastic, metal and ceramics. Creative Biolabs has employed a large number of top-level scientists and purchased intelligent equipment so that is capable of providing one-step, customized cell therapy services with many different cell lineages through this latest 3D bioprint technique.

3D Bioprint Introduction

3D bioprint is a tool for manufacture that utilizes 3D printing and 3D printing-like techniques to create living tissues and functional organs. This method combines cells, growth factors, and biomaterials to fabricate biomedical products that maximally simulate natural tissue features. Generally, 3D bioprint works in a layer-by-layer manner by which materials gradually deposited to obtain the bioprinted structure. This strategy covers a wide spectrum of starting materials, classified into metals, ceramics, natural polymers, synthetic polymers, and various combinations of these. The materials are also known as bioinks, a hydrogel biomaterial, allowing the adhesion and proliferation of living cells.

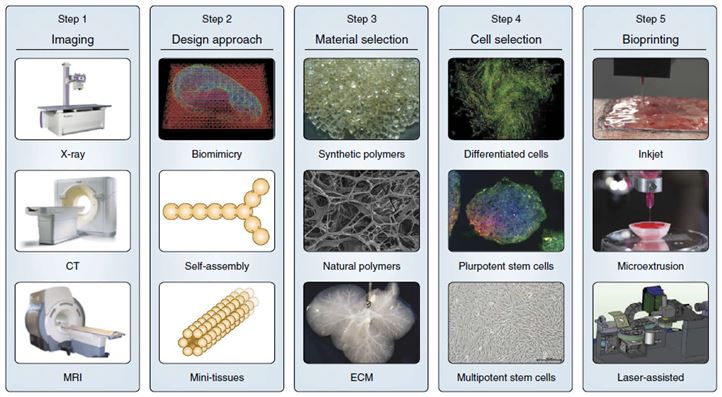

A typical process of 3D bioprint technology includes below steps, imaging, design approach, materials selection, and bioprinting. This strategy has been widely used in biological and clinical research, which could revolutionize the diagnosis and treatment of diverse medical conditions.

Fig.1 A typical process for bioprinting 3D tissues. (Murphy, 2014)

Fig.1 A typical process for bioprinting 3D tissues. (Murphy, 2014)

Classifications

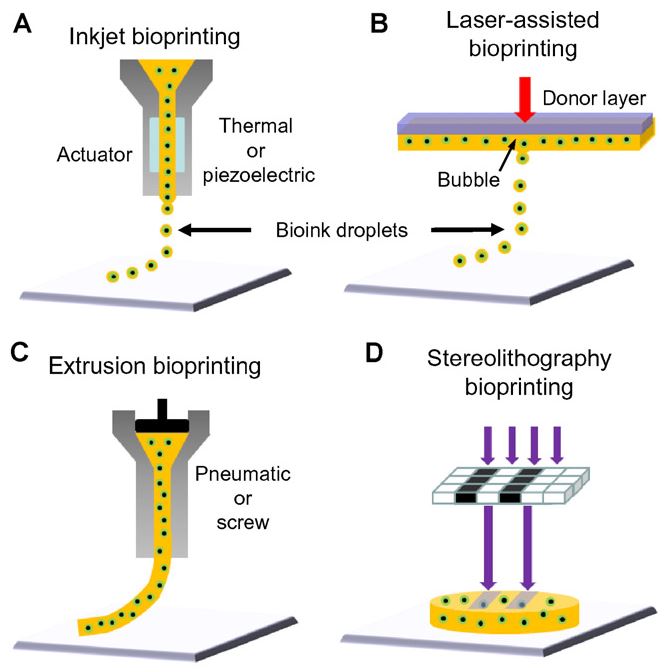

- Inkjet printingInkjet bioprinting is the first bioprinting method, very similar to conventional 2D inkjet printing. Inkjet printer can eject small droplets of cells and hydrogel sequentially to make up tissues.

- Laser-assisted printingLaser-assisted printing derives from a laser direct-write and a laser-induced transfer technology. Its bioprinter uses a laser to vaporize a region in the donor layer to form a bubble that promotes a suspended bioink to fall onto the substrate.

- Extrusion printingExtrusion printing is modified from inkjet printing. In order to print viscous materials the inkjet printer cannot deposit, extrusion bioprinter uses an air-force pump or a mechanical screw plunger to extrude a liquid cell-hydrogel solution continuously.

- Stereolithographic bioprintingStereolithographic printer uses a digital light projector to selectively crosslink bioinks plane-by-plane. This system is able to print hydrogel patterns with 50 μm resolution.

Fig.2 Four types of bioprinting. (Mandrycky, 2016)

Fig.2 Four types of bioprinting. (Mandrycky, 2016)

Applications

- Drug screening & testing

- Testing of cosmetics and other consumer goods

- Regeneration medicine

- Food and other animal products

- Tissue engineering

- Bionics

- Personalized medicine

- Education

3D bioprint exhibits numerous applications. It is mainly used for the generation and transplantation of several tissues and organs, including skin, bone, cartilage, vascular grafts, tracheal splints, and heart tissue. It is also a great way for medical scientists to perform assays in laboratories. Instead of testing on animals, it makes it possible to examine directly on human tissue or organs since these bioprints have exact same properties and reactions. Another interesting application of 3D bioprint in the medical context is to manufacture anatomical models, which are required for surgical training.

Key-benefits

3D bioprint is a process of creating cell patterns by making use of live cells to produce living tissues, bones, blood vessels, and even whole organs in many applications of healthcare and medical industries. It involves constructing tissues wherein cell viability and function is preserved within the printed construct. There are several advantages of 3D bioprint summarized as follows:

- Offer transplantable organs to replace donors

- Generate a variety of tissues

- Low risk of cell rejections

- Replace volunteers in drug testing

- Avoiding laboratory animal testing

- Reduce organ trafficking

3D Bioprint Service in Creative Biolabs

3D bioprint as an advanced cell therapy technology has attracted increasing attention in academic research and clinical medicine. In contrast with conventional methods, 3D bioprint is able to potentially provide a high-throughput and affordable means to assemble cells to build up complex tissues. Besides, you may interest other bioprinting servicers we introduced as below to propel your projects.

3D bioprint can print tissues or organs to assist cell therapies and help drug research. In Creative Biolabs, we are capable of offering 3D bioprint services with a high-resolution cell deposition and cost-effectiveness. Furthermore, we also devote to developing its technical strengths by printers, to generate artificial human organs that reproduce biological functions.

If you want a quote in detail for related customized services or have any special requirements, please feel free to contact us.

For lab research use only, not for human therapeutic use.

References

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat Biotechnol. 2014, 32(8): 773-785.

- Mandrycky, C.; et al. 3D bioprinting for engineering complex tissues. Biotechnol Adv. 2016, 34(4): 422-434