Chemists at the University of Helsinki have created a method of using nanofibers and thin-film biomaterials as orthopedic scaffolds to help regenerate bones and to help implants settle into their new home. The nanofibers are made of electrospun hydroxyapatite, a naturally occuring mineral form of calcium apatite.

Bone is a fibrous nanocomposite material with a complex hierarchical system of different macro-, micro- and nanostructures. The structure elegantly supports the bone cell functions and facilitates bone remodeling by cellular activity. Injuries and diseases, e.g. osteoporosis, can cause bone fractures and loss that need to be treated with orthopedic implants.

In future, it may be possible to use nanofibres to improve the attachment of bone implants, or the fibres may be used directly to scaffold bone regeneration. This would aid the healing of fractures and may enable the care of osteoporosis. This is detailed in a new dissertation.

In his doctoral research, Jani Holopainen of the Department of Chemistry at the University of Helsinki has developed processes for fibrous and thin-film biomaterials that can be used as scaffolding for bone regeneration and in other bone impants. He also studied the apparatus used for nanofibre production.

SYNTHETIC BONE-LIKE MATERIAL

– At best, bone-reforming scaffolds that regenerate at the same rate as bones could be used as implants. The scaffolds activate the bone cells to generate new bone that slowly replaces the disintegrating scaffold and the impant exits the body naturally without separate removal surgery, Jani Holopainen says.

Holopainen selected hydroxyapatite, the main component of the bone mineral, as the focus of his research. This is why the synthetic hydroxyapatite structures he has developed are very compatible with bone.

PROTOTYPES MANUFACTURED IN KUMPULA

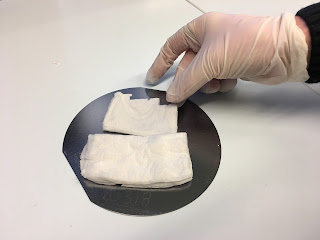

Holopainen developed the electrospinning apparatus for producing hydroxyapatite fibres and a new kind of needleless twisted wire electrospinning setup, which is more productive than the generally known electrospinning method. The prototypes for the equipment used in the research were manufactured at the Department of Chemistry at the University of Helsinki. The equipment will have to be developed further in order to enhance production to an industrial scale.

– This promising method still has a long way to go before it will become a real medical application, though cellular tests have already been made, says Professor Mikko Ritala of the Department of Chemistry and the Atomic Layer Deposition centre of excellence at the University of Helsinki, who was the advisor of the doctoral research.

The aim of this work was to investigate the preparation of thin film and fibrous biomaterials for bone implants and scaffolds. New processes were developed for various biomaterials and their properties were thoroughly characterized. A method to convert CaCO3 nanostructures to nanocrystalline hydroxyapatite (HA) by treatment in phosphate solution was used to prepare HA thin films and fibers from atomic layer deposited (ALD) and electrospun CaCO3, respectively.

HA fibers were also fabricated conventionally by annealing electrospun composite fibers that incorporated Ca and P precursors. Biocomposite fibers of HA nanoparticles and polylactic acid (nHA/PLA) were directly electrospun. These different nanofibers are highly interesting for bone scaffolds owing to their high surface area and the structural similarity to the fibrous nanostructure found in bone. However, conventional electrospinning is limited by its modest production rate. A needleless twisted wire electrospinning (NTWE) setup was developed to increase the production rate and was studied for the preparation of HA fibers for the bone scaffolds. Solution blow spinning (SBS) and electroblowing (EB) of HA were studied as other upscaling alternatives.

https://www.helsinki.fi/en