Researchers at Northeastern University are developing patient-specific 3D printed medical devices for newborns. Anything to do with babies tugs at the heartstrings of most anyone, so the idea of patient-specific catheters made to offer greater support to premature newborns is exponentially inspiring. Their innovative designs are different indeed in that they use magnetic fields to mold 3D printed material into customized devices and products. Meant to be more durable, as well as lightweight, Northeastern University has developed an innovative 3D printing technology that uses magnetic fields to shape composite materials into patient-specific products.

Through the study of fiber composites that are light yet amazingly strong, the researchers are able to “combine real-time colloidal assembly with existing additive manufacturing technologies to create highly programmable discontinuous fibre composites.” They refer to their new technology as 3D magnetic printing, which allows them to use the inspiration of nature in re-creating “complex bioinspired reinforcement architectures that deliver enhanced material performance compared with monolithic structures.” The biomedical devices they are developing ensure greater reliability and an appropriate fit, as the magnets, causing superior alignment in the material fibers, allow much better precision in 3D printing.

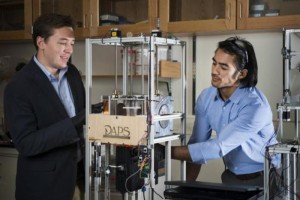

“I believe our research is opening a new frontier in materials-science research. For a long time, researchers have been trying to design better materials, but there’s always been a gap between theory and experiment,” said Joshua Martin, the doctoral candidate who helped design and run the experiments. “With this technology, we’re finally scratching the surface where we can theoretically determine that a particular fiber architecture leads to improved mechanical properties and we can also produce those complicated architectures.”

This is particularly relevant to an area like catheters for preemies, as traditionally the devices only come in the typical standard, one-size-fits-all model. While being able to make these devices obviously opens the door to a plethora of other ideas in areas requiring complex and miniature architectures, the neonatal area is a perfect place to start as a priority as the 3D printed devices not only help offer life supporting fluids and eliminate discomfort, but also prevent errors that could have serious consequences. “With neonatal care, each baby is a different size,” said Randall Erb, assistant professor in the Department of Mechanical and Industrial Engineering and lead researcher on the project. “If you can print a catheter whose geometry is specific to the individual patient, you can insert it up to a certain critical spot, you can avoid puncturing veins, and you can expedite delivery of the contents.”

Obviously, we’ve followed many different cases of 3D printed devices at this point, but truly what stands out here is the use of magnets controlling the mechanics of the material and arranging the ceramic fibers in a specific way, reinforcing all the nuances of the device. “We are following nature’s lead,” explains Martin, “by taking really simple building blocks but organizing them in a fashion that results in really impressive mechanical properties.” The fibers are coated with iron oxide, already FDA approved to be used in an application like this. This is what causes them to be magnetized, after which ultralow magnetic fields are applied to separate sections of the material with the fibers put into liquid plastic to achieve the desired result. The magnetic fields are easy to apply, and according to Erb, they are not harmful or invasive to the human body. Using SLA, each six-by-six layer takes about a minute to 3D print.

These 3D printed neonatal catheters are a great example of how 3D printing can improve quality of life and in this case, from nearly day one offering vehicles for nearly half a million new lives started prematurely each year, depending on tubes to receive oxygen and nutrients.

For more information please visit: www.northeastern.edu

Comments are closed.