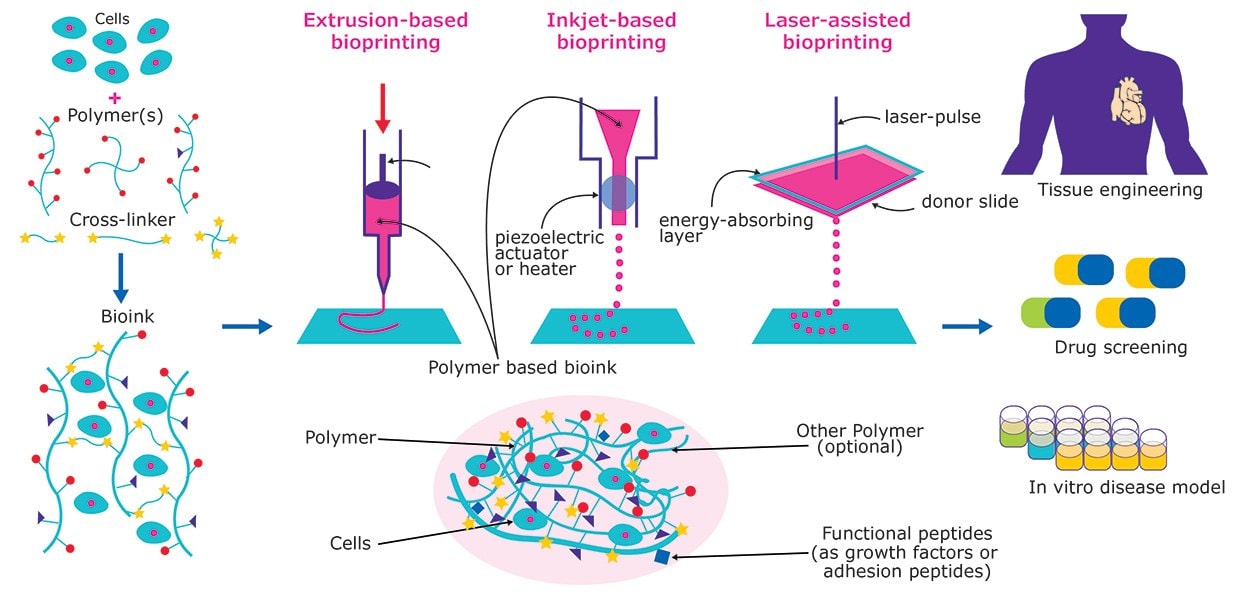

Bio-inks are materials used to produce engineered/artificial live tissue using 3D printing. These inks are mostly composed of the cells that are being used, but are often used in tandem with additional materials that envelope the cells. The combination of cells and usually biopolymer gels are defined as a bio-ink.

Bioinks may be made from natural or synthetic biomaterials alone, or a combination of the two as hybrid materials. In certain cases, cell aggregates without any additional biomaterials can also be adopted for use as a bioink for bioprinting processes.

Bioprinting is an emerging technology with various applications in making functional tissue constructs to replace injured or diseased tissues. It is a relatively new approach that provides high reproducibility and precise control over the fabricated constructs in an automated manner, potentially enabling high-throughput production. During the bioprinting process, a solution of a biomaterial or a mixture of several biomaterials in the hydrogel form, usually encapsulating the desired cell types, termed the bioink, is used for creating tissue constructs.

The new stem cell-containing bio ink allows 3-D printing of living tissue, known as bio-printing. The new bio-ink contains two different polymer components: a natural polymer extracted from seaweed, and a sacrificial synthetic polymer used in the medical industry, and both had a role to play.

They must meet certain characteristics, including such as rheological, mechanical, biofunctional and biocompatibility properties, among others. Using bio-inks provides a high reproducibility and precise control over the fabricated constructs in an automated manner. These inks are considered as one of the most advanced tools for tissue engineering and regenerative medicine (TERM).

Bioinks contain living cells and biomaterials that mimic the extracellular matrix environment; supporting cell adhesion, proliferation, and differentiation after printing. In contrast to tradtional 3D printing materials, bioinks must have: Print temperatures that do not exceed physiological temperatures.

This bioink can be cross-linked or stabilized during or immediately after bioprinting to generate the final shape, structure, and architecture of the designed construct. Bioinks may be made from natural or synthetic biomaterials alone, or a combination of the two as hybrid materials. In certain cases, cell aggregates without any additional biomaterials can also be adopted for use as a bioink for bioprinting processes.

An ideal bioink should possess proper mechanical, rheological, and biological properties of the target tissues, which are essential to ensure correct functionality of the bioprinted tissues and organs. In this review, we provide an in-depth discussion of the different bioinks currently employed for bioprinting, and outline some future perspectives in their further development.